Laser Melting

Laser Melting-Sintering machines are tools that, according to an additive process, produce sub-structures for the dental from metal powders.

The raw materials which are used are in fact Biomedical Titanium and Cobalt Chrome powders that are measured and selected to reach a particle size of less than 10 micrometers and guarantee a high quality and precision systematic processing.

Following the CAD indications, the machine produces the structure by fusing the layer-by-layer metal powder using a high-intensity laser. The structure finished this way is sintered in an oven to eliminate the tensions and be detached from the support safely.

PRODUCTION PROCESS

- Scan of the impression or of the master model in the laboratory / dental studio

- Specialized technicians model the scan file to produce a digital version of the final product (CAD software)

- The file modeled this way is sent to the machine which interprets the supplied instructions and independently manufactures the product that will be finished by our collaborators (CAM software)

USED MATERIALS

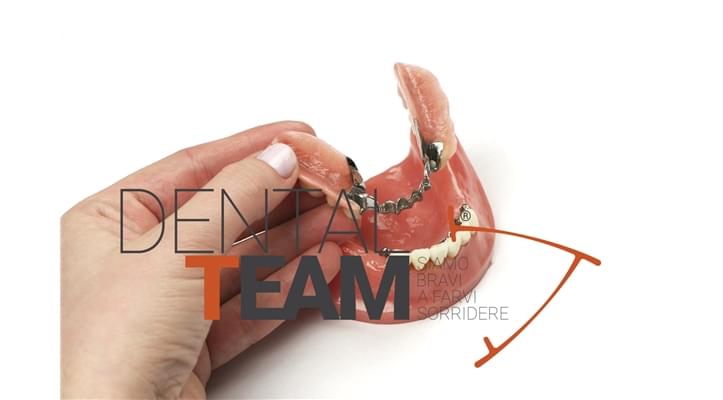

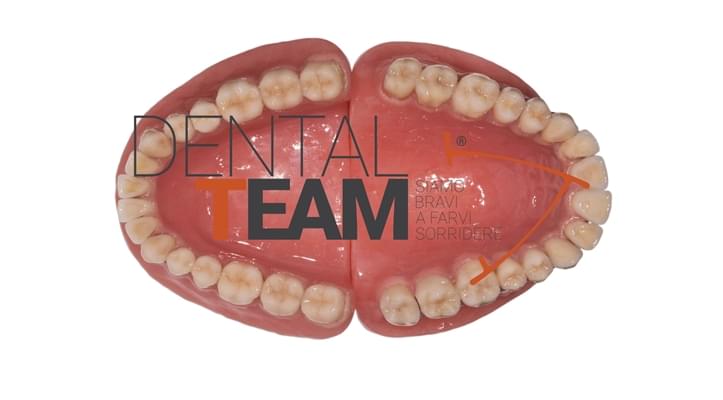

Photo of

Gallery of pictures

Foto 1 di 20